Website Sponsor Brazilian Designer Jeans |  |

Information about Jeans ™

Home | History of Jeans | How Jeans are Made | News, Products & Services | References | Contact Us

1st Stage of Making Jeans

|

|

Making a pattern starts with a thick durable paper. |

Sample of one pair of jeans must be aproved first. |

|

|

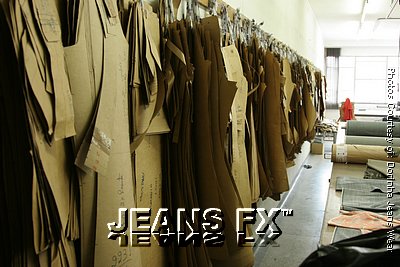

Wall of jean patterns stored until needed again. |

One pair of jeans can have 12 to 16 pieces. |

|

|

| Companies have pattern makes exclusive. |

Or hire a pattern makes per job or contract. |

|

|

Many samples may be made before one gets approved. |

Pattern, spec sheet and all the denim piece to make one sample. |

|

|

|

|

Pocket designs can be hand drawn or computer drawn. |

A sample room will have up to 14 different sewing machines. |

|

|

Machines all have a different purpose to make one pair of jeans. |

|

|

|

Thead comes in differnt thickness and color. |

Expensive thread is a blend of cotton and nylon. |

|

|

Patterns can be laid on paper to be traced. |

|

|

|

Denim comes in many types of quality & weight.. |

Good quality fabric can cost up to $12.oo for one pair of jeans. |

|

|

Computer programer puts many pattterns on a role of paper. |

Paper then laid on top of the fabric out up to 100 layers. |

|

|

Masked used for safety. Working conditions in a good factory. |

|

|

|

|

|

Back - Next Stage - Top of page

Back

Copyright 2025 JEANS FX™ all rights reserved. Privacy Policy | Contact Us